SV200

Specifically designed for removing the residual resin after plugging.

Descriptions

Designed for residual grinding of PCB boards after grinding, using vacuum adsorption technology to fix the PCB board on the table, manually pull the grinding head to a specific position and drive it to rotate in order to partially grind the PCB board.

Features

★Grinding area (size) and precision can be switched quickly.

★Replace the traditional manual grinding, accurate control of copper thickness accuracy.

★The grinding current is accurately displayed on a high precision digital ammeter.

|  |  |

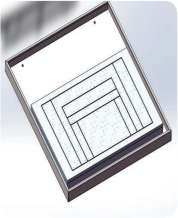

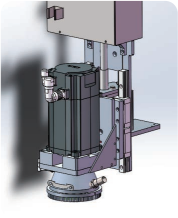

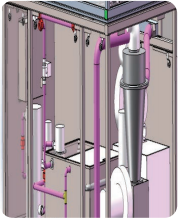

Partitioning adsorption, easy for changeable on different size panels. | The grinding head. | The air and unit. |

Specifications

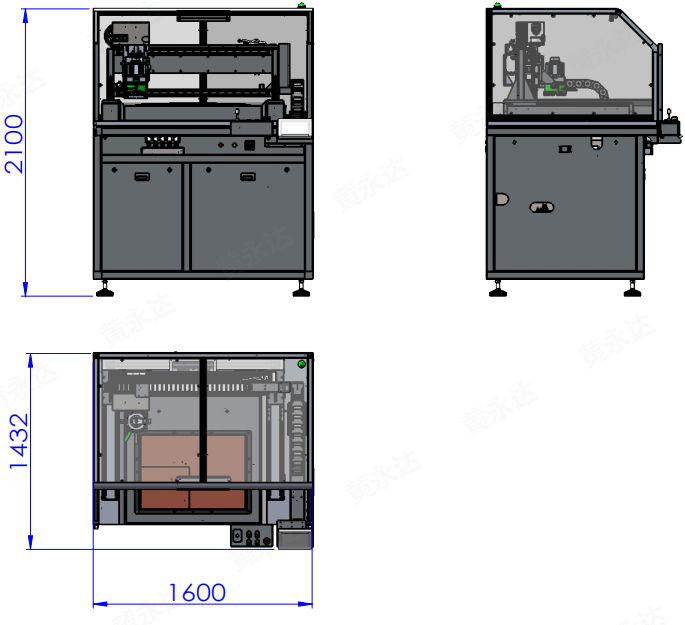

Equipment Size | 1600*1432*2100mm |

Panel Size | Min: 12*14In(304.8*356mm) Max: 21*30In(536*762mm) |

Thickness of substrate | 0.3-15mm |

Grinding accuracy | 0.25mil(MAX.) |

Speed of grinding head | 1000/1500/2000rpm |

Working Height | 1350mm±50mm |

Make-up pipe calibre | 20mm(4-point pipe) |

Communal Requirement

Electricity needs | |

Electronic | AC380V;3P+N+PE,50Hz |

Power (output) | 5KW |

Required amount of air pressure | ≥0.6MPa;φ6mm(dry air) |

Recommended space around machine | 800mm |

Weight | 900KG |

Equipment installation environment (temperature, humidity and dust-free requirements) | Clean room Temperature requirement: 22±2℃ Humidity requirement: 50±5% |